Article 5 - Composition Bowls

ARTICLE 5 - Composition Bowls

(Originally published in 1998 and revised in 2009)

My last article covered the manufacture of "Woods" for this

article I will cover the manufacture of Composition Bowls -

confusingly still known as "Woods"!!

We have to thank the games spread overseas for the introduction

of Composition Bowls. As the sport developed in the Southern

Hemisphere, which enjoys a hotter climate than the U.K., it quickly

became apparent that Lignum Vitae was not a suitable material for

bowls to be made from, basically it warped and cracked.

The Australian, billiard, company Alcock & Co. employed Hr.

W. D. Hensell who in 1918 with Dunlop Rubber Co. produced the first

Ebonite bowls. Mr. Hensell set up his own business turning the

Dunlop Rubber Co. material into bowls. This proved to be so

successful that Lignum Vitae bowls were no longer imported into

Australia. In the 1930's Dunlop Rubber Co. decided to not only make

the material but also to do their own turning and finishing.

Which precipitated Mr. Hensell and his son Ray to search for a

replacement material and so after many failures the company was

able in April 1931 to produce the first successful Phenol

formaldehyde Composition Bowl.(Note for coloured bowls Melamine is

the preferred material). Since that date the development of the

modern bowl has progressed forward but still uses the Phenol

formaldehyde as the basis. What a lot of bowlers do not appreciate

is the science and engineering that goes into the production of

their set of bowls. Very few sports have such high specifications

for their equipment, which can then be purchased so cheaply.

Whilst I hear you all say - he would say that his company

manufactures bowls - just bear in mind the information in the

following paragraphs.

To start at the beginning, the phenolic powder has to be

produced and this is a science and a skill in itself. All

manufacturers use powders with different specific gravities to

achieve their desired weights for their various models. So not only

does the powder manufacturer have to design the powders to suit the

moulders requirements for the flow characteristic, colour, surface

finish, etc. that they require, but they also have to ensure that

the specific gravity meets the specifications and all these

specifications must be consistently met.

The machining, of the material, really relates to the final

manufacturing of the bowls but the Powder Producer has to take this

into consideration as well as the final surface finish and, as

already mentioned the colour. This last specification may surprise

a few, when they consider that the majority of bowls are black -

but there are many shades of black achievable from a very, very

dark grey to a jet black.

After the ingredients are blended the initial process to produce

the Powder can commence which involves both heat and pressure. The

chemical bonding process begins at this point (but then it is

stopped), and the resulting "Cake" is ground to the powder size

specified by the moulder. To ensure, at all stages of production,

the very stringent specifications laid down are achieved, the

producers have their own in-house quality control laboratory. This

enables them to test for conformity to the demands of the moulders

and as an example of this, the main U.K. supplier of the powder has

met with the requirements laid down to achieve BS5750.

All the mixes are checked to ensure that grain size and mix are

correct. The final check for this is also made for the blended

powder before despatching it to the moulder. Checking the specific

gravity is correct is a regular feature throughout the production

and the specific gravity can be altered to ensure conformity to the

requirements of the customer. They even produce small mouldings of

the final blend, which they can machine to check the rigidity and

shrinkage so that they can ensure that they fully meet the demands

and specifications of the moulder.

The next stage is the moulding of the blank, which is again a

very specialist task. Even some of the U.K. top moulding companies

cannot achieve the desired results. I believe it is still true that

the moulded "blank" for a bowl is still the largest solid mass of

phenol compound moulded successfully.

As the basic blend powder is comparatively expensive, we, and

our competitors, have moulds of different sizes to suit the

different models and size of bowl which we produce. This avoids

producing too much waste during the turning operation. Basically

however the process starts by taking the specified quanity of

phenolic thermoset powder, which is then carefully measured out to

ensure that the exact amount of powder is used for that particular

mould.

Before the powder is placed into the

mould it is pre-heater which ensures that the moisture is removed

and that the "Cake" is heated right through. This also restarts the

chemical bonding process and thus helps reduce the time required in

the mould.

After the pre-heating is completed the "Cake" is put into a

computer controlled high tonnage compression moulding press. The

platens and mould of which, are heated to a surprisingly high

temperature. The "Cake" which is then pressed into the final shape

remains in the press for some time to allow the 'Cake' to be fully

baked! It then emerges as a "blank" which we can use in our

computer controlled lathes.

However, this isn't the final part of the moulding process, the

blanks now have to be left to cool under controlled conditions so

that the full cure can be successfully completed and then they are

sonic checked for voids before being ready for use. We also at

Drakes Pride like to leave them to "settle" so that any moulding

stresses will have gone before we turn same.

You will now realise, the moulding processes are also highly

complex and the skill required to ensure the gases that develop

during the chemical bonding and pressing are released and not

trapped in the mould. This process has been improved and developed

over the years.

As already mentioned there are very few moulders who have the

skill or the knowledge to produce these very large mouldings and as

such they too have had to have in-house laboratory testing which is

specific to their requirements. We are now at the stage were a

blank is available for the manufacturers to turn their models of

bowls from.

Drakes Pride was the first company to use computer controlled

turning centres in the manufacture of bowls and this required in

1979/80 the help of Liverpool University Computer and Mathematics

Departments to be able to produce the required geometric shapes.

The programmes developed by each manufacturer for use on their

C.N.C. equipment require skilled and highly trained specialists to

not only, initially, write them but maintain them. All the

manufacturers now use computer controlled lathes and so the bowls

produced to-day are made to higher specifications and tolerances

than over before. This in turn has put further pressure on the

moulders and the powder producers to achieve tighter and tighter

specifications.

When the blanks are taken from our

store for turning, the first of many inspection, is carried out. To

ensure that the blanks issued are consistent for weight, and an

initial bowl is turned to confirm that the bias settings on the

machine are correct for that batch production to be run off. During

the production each turned blank is checked for weight, conformity

and further bias tests will be carried out. Bowlers would recognise

the product as it comes off the lathe but finishing processes are

then required such as engraving of the brand, model, serial number,

W.B.B. Stamps(now World Bowls Ltd. stamp), etc.. From our

manufacturing the serial number lets us trace back each individual

set of bowls not only to the day they were produced, but also to

the operator who turned them, the operator who engraved them and

also which particular batch of blanks was used in the manufacture.

This is all part of our quality control.

During the finishing process examination and the testing is done

and whilst the W.B.B.(now World Bowls Ltd.)allows a tolerance of

15gms within a set, we only allow ourselves a maximum of 8gms

tolerance and our target is always to be considerably less than

that.

Bias testing on the table is something, that as you know, I

could write about for a long time, suffice to say at this point,

that all the acts of bowls in their final process are table tested

to the guide-lines an laid down by the W.B.B.(now to the

regulations laid down by World Bowls Ltd.)

You will therefore now perhaps realise that bowls and the work

involved in the manufacture of bowls, is more complicated than you

may have imagined, and why initially I suggested that they were a

very cheap sporting item. I hope you will now appreciate the true

value of your bowls. The W.B.B.(now WB for World Bowls Ltd.)stamp

is for a 10 year period (which includes the year of issue). One

should remember that for outdoor play were top dressing and gritty

fertilisers are used, the specified bias may not remain true. Also

when a bowler plays with just a pair of bowls they tend to use the

same pair. After a few years that pair of bowls will almost

certainly run differently to the other pair that have not be used..

So taking your bowls for re-testing every 5 years should be

considered by bowlers especially those who who are keen on their

sport and play regularly, otherwise every 10 years is sensible and

should be recognised by the National governing bodies. At that time

the bowls can be rebuffed/repainted so that their condition remains

good. Also, like all other pieces of sporting equipment bowls do,

believe it or not, become superseded by the newer products. The

newer bowls are not only made too much higher specifications but

will be turned too much tighter tolerances.

The newer models of bowls are designed for specific purposes,

e.g. the UK Drakes Pride Professional are the bowls specifically

designed by my company, for indoor and outdoor use, whilst our

Melbourne model( replaced in 1998 by the Professional Plus which

has subsequently be superseded by the Jazz)is the one designed for

outdoor U.K. greens. With the Advantage model design for indoor

usage. If a player used the Melbourne Model(now the Jazz) on an

indoor green the player, they would not be using the type of bowl

which has been "tuned" to the current indoor playing surfaces, it

may, however suit their style of play!!

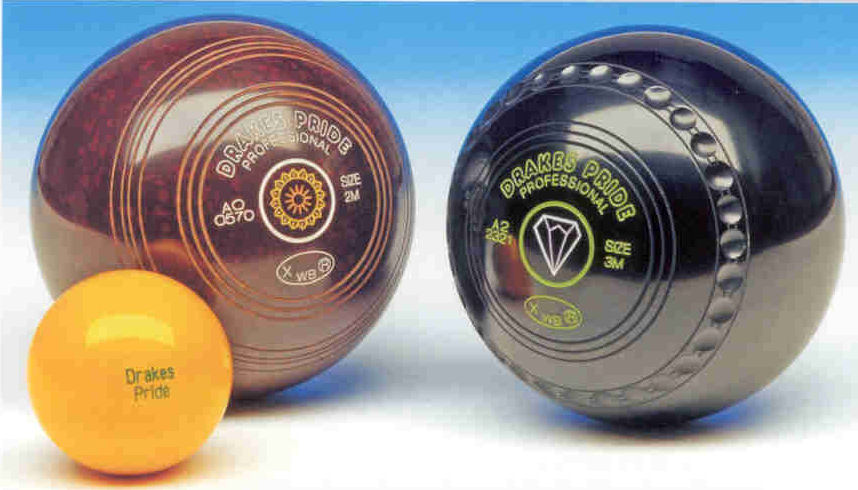

Drakes Pride Speckled Brown &

Black phenolic material

Drakes Pride Coloured Bowls 2010

using melamine material

(Since 2010 the range of colours has been greatly increase and

there are now really too many to show!! see www.drakespride.co.uk

for current range of colours available)

(Since the World Bowls Board,now World

Bowls Ltd, meeting in 2000 coloured bowls have been allowed. Prior

to that decision only Black or Brown bowls could be used. Phenolic

material has for coloured bowls been replaced by Melamine as it has

better UV stability but Melamine can really only be used for Heavy

weight models as its basic specific gravity is high.)

© Peter Clare 2010 © E.A. Clare & Son Ltd. 2018 This article

can only be used in part or whole with permission of E.A. Clare

& Son Ltd.